Compact Systems│Sensors│SK-go!® software

SK-go!® is your universal tool to control and to analyze the effectiveness of your manufacturing operation. Select from the extensive list of software modules which functions and reports are relevant to your company. All modules are using the same data base ensuring that the collected information is uniform through all applications. A data import and export interface to your ERP-system guarantees that all information is exchanged with your organizational data processing system.

The SK-go!® software analyzes the collected data and converts them into easy-to-understand and ready-to-use graphics. Special emphazis has been put into ease of operation. All commands and all graphs are self explanatory.

Please see below the most common functions and modules:

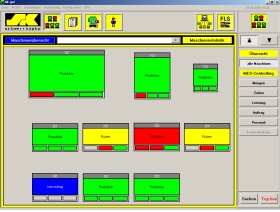

The SK-go!® shop floor viewer gives you a comprehensive

look at the current shop floor situation:

• graphical shop floor layout with coloured indication of

machine status

• current down reason and length of down-time

• alert indicators (traffic lights) for critical situations

• MES-Controlling function screens all machines in respect

to their targets (with indicator lights)

Just click on the machine symbol and obtain an array of data

concerning current job progress and efficiency, and the

performance of the last shifts.

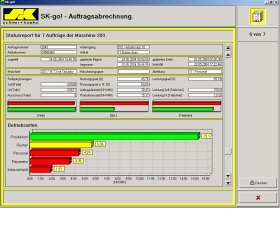

Expand your system by relating the collected data to the running parts. Simply start and terminate jobs on your machine data terminals. This step will give you in addition:

• job performance reports (efficiency, quantities, etc.)

• all data available for costing

• job sequences

• job comparison

And this information is not just available for the jobs of the

last 6 weeks, but as far back as you want!

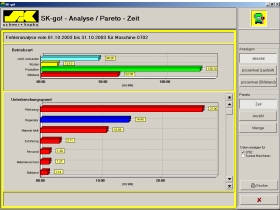

Create your own list of down codes and select the relevant

code on your machine data terminal each time the machine is

down.

SK-go!® will now deliver further shop floor details such as

down code statistics and error frequencies for any selection

or combination of time frame, machine number(s), jobs,

or parts.

So you will be able to locate weak points quicker.

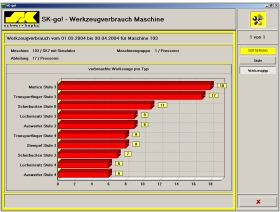

SK-go!® offers an attractive and very easy-to use function to keep an accurate record on the number of tools consumed.

Each time the operator reports a tool change as the reason for being down, the machine terminal will prompt a tool structure (text listing, CAD-drawing, graphs, etc.) from which he can select the tool(s) just exchanged. At the end of each job, you will have exact information about number of tools used for this job, and the associated cost. The achieved tool life is automatically recorded at the same time.You can have detailled tool life reports at your finger tips such as

• average tool life for each type of tool

• tool consumption listed e. g. by machine, job, part, time period

• “hit parade” of tool types, etc.

• job scheduler for order fine planning incl. machine work load graphs and job distributor

• reporting system

• batch change recorder with traceabilty logbook

• change over preview function

• change over protocols

• job speedo

• calcucation of OEE factors

• premium wage calculating system with on-line link to shop floor performance data

• personnel data collection: report to and from machine

• shift calendar

• shift planning

• facility management: automatically controls your auxilliary supplies such as compressed air, heating, ventilation, etc.

according to actual demand

• MES-controlling with warning light indicators

• Process visualization: live-view from your desktop into the process parameters of all connected machines