Compact Systems│Sensors│SK-go!® software

The success of each monitoring system is largely dependant upon the quality of the measured signal and thus, on the selected type of sensor and the chosen location. We design, manufacture and sell a wide variety of analogue and binary sensors for various areas of industrial measuring tasks such as force, strain, pressure, tension, acoustic emission, electrical motor load, linear travel, rotary angle etc. A range of signal amplifiers is available to properly condition the measured signals. All sensors are designed to work with our process monitoring systems.

Piezo-electric sensor in a flat disc format used to measure force and/or acoustic emission signals on machine parts. The sensor is easily installed by glueing it to the surface of a machine part, or by cemeting it into a prepared pocket. The sensors are available in diameter from 5 - 25 and thickness from 0,5 - 1,0 mm. DISC FLEX sensors typically produce a very strong output signal

Piezo-electric sensing probe to measure strain and forces inside machine parts. The sensor is installed into the industry-standard 8-mm bore which runs perpendicular to the direction of the force to be measured. The sensor can be fitted in a recessed way in deeper bores. A special SUPERFLEX-Tool is available to position and to tighten the sensor in the correct way.

Piezo-electric sensing probe to measure strain and forces inside machine parts. The sensor is installed into a 8-mm bore which runs perpendicular to the direction of the force to be measured. The SUPERFLEX-S short sensor is especially designed for applications where forces must be measured close to the surface of the machine part. A protection cap is available to guard the sensor head and the cable exit from external damage.

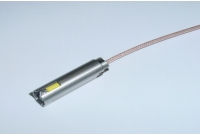

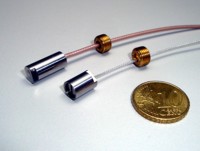

Axflex and Mini-Axflex sensors are piezo-electric sensing probes which measure force in axial direction. They typically are installed into bores that run in the direction of the forces to be measured. A special brass nut is used to tighten the sensor inside its bore.

Piezo-electric or strain-gauge sensing elements can also be fitted directly into modified machine parts or tool components which take loads, forces or strains during the manufacturing process.

Piezo-electric sensor for measuring force and/or acoustic emission signals on the surface of machine parts or tool components. This sensor is simply bolted on to the part by means of a M8 fastener. The BRIDGEFLEX sensor can be easily removed and re-used elsewhere.

Bolt-on surface strain sensor based on strain-gauge sensing elements and an integrated, high resolution amplifier. The X-Flex sensor e. g. can be simply fastened to the frame of a machine such as a press to measure actual press loads (tonnage sensor). The sensor can be calibrated to give true tonnage readings.

Sensor to measure the power consumption of an electrical motor. This sensor is used to detect overload situations, or to register the breakage of tools such as drills or taps. The sensor is simply wired into the power feed lines to the motor.

Load sensors used to measure absolute forces in applications such as press-fit assembling, rivetting, clinching, testing, etc.. The load cells typically are supplied with a calibration certificate. These sensors are available in a wide variety of sizes and shapes to suit the different needs in respect to mounting space restrictions and load ranges.

Sensors for accurate measurement of rotary angles (e. g. on machine crank shafts) or linear travel of machine parts such as rams or slides. These sensors are used when precise monitoring of force vs.travel or force vs. crank angle is required. A wide range od sensor types is available to meet the different applications.